scalable

unlock

bio-production

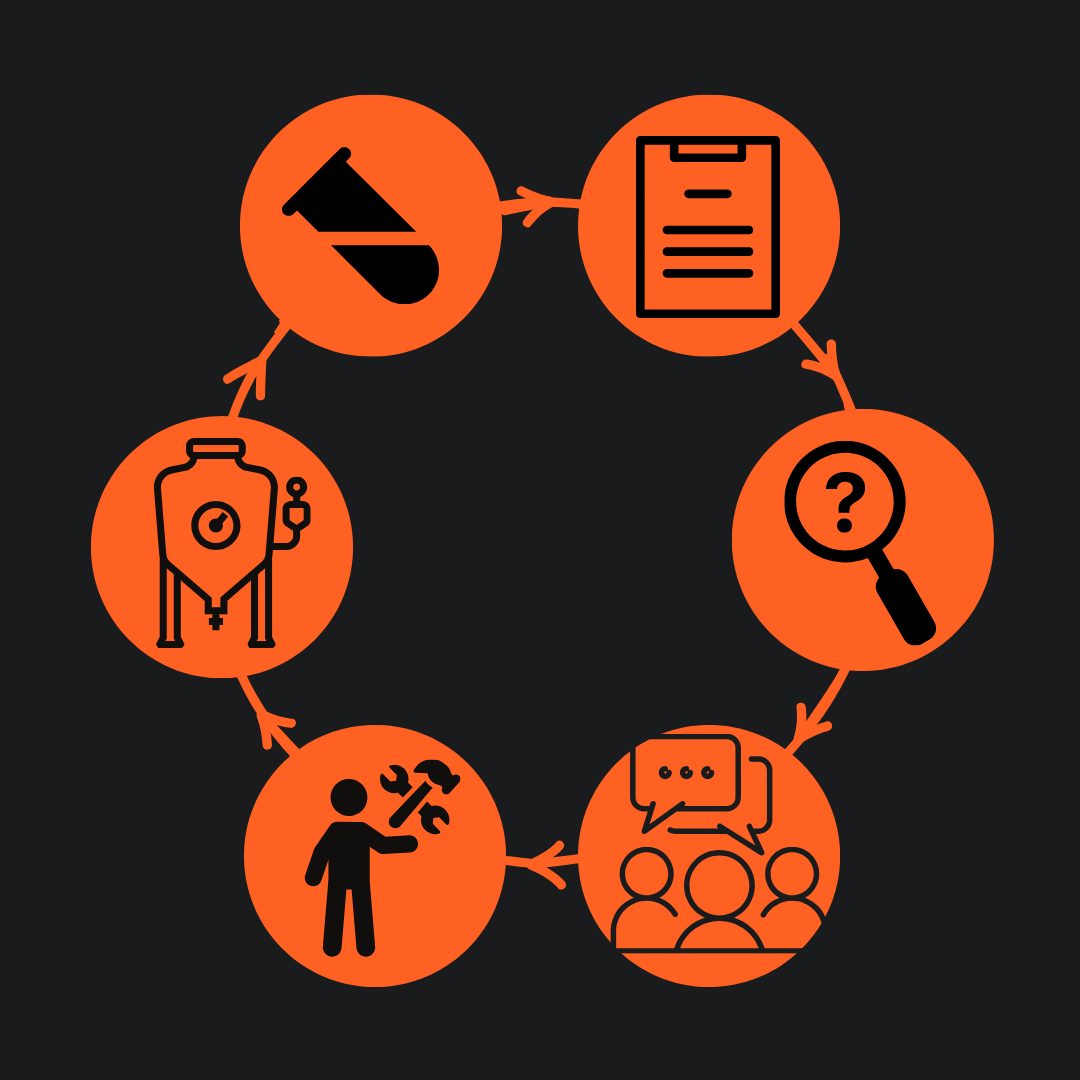

Current practices

Volatile environments with unscalable energy-intensive control systems

collect sample

go to

fermentor

carry out tasks

log data

analyze data

decision making

Intensive lab-based sampling, energy-intensive control systems, and unknown variables. High-yield variability and inconsistent production.

precision-fermentation intelligence

with exocule

Yield Scalable with intelligent operated control systems

automated-sampling

tasks carried out

Data logged, analyze &

optimized

granular biological and environmental data in real-time. Removal of many lab-based processes. automated optimization via process control and continuous improvement through machine learning

Every biofermentor optimized

OUR TECHNOLOGY

Vision & Intelligence for Every Bio-fermentor

Every Bio-fermentor

economic production at your fingertips

01

Closed-Beta programme (2023) | CLOSED

CLOSED

PROJECT: Singapore/US Partnership

FOCUS: Optimizing precision-fermentation food ingredients production using AI

OPTIMIZING TARGET PROTEIN YIELD IN YEAST SYSTEMS

02

Closed-Beta programme (2024) | OPEN

FULL

PROJECT: US/Europe

FOCUS: Precision fermentation optimization and control system integration. Reducing and optimizing energy use with an intelligence approach

REMOVING DEPENDENCES ON ENERGY EXPECTIVE CONTROL SYSTEMS, FOCUSING ON OPTIMIZING ENERGY USE AND TARGET INTERVENTION IN REAL-TIME

“The potential is for civilization-scale flourishing, a world of abundance not scarcity, supporting a growing global population without destroying the planet.”

Drew Endy,

Stanford University